Slot Profile Tolerance

Let’s go back to the question box —

When slots are intended to be used for holding only, tolerances can be 0.0 + 0.010 inch or H12 Metric (ISO/R286); when intended for location, tolerance can be 0.0 + 0.001 inch or H8 Metric. Corners of T-Slots may be square or may be rounded or broken to the indicated maximum dimensions at the manufacturer's option.

Slot Profile Tolerance Chart

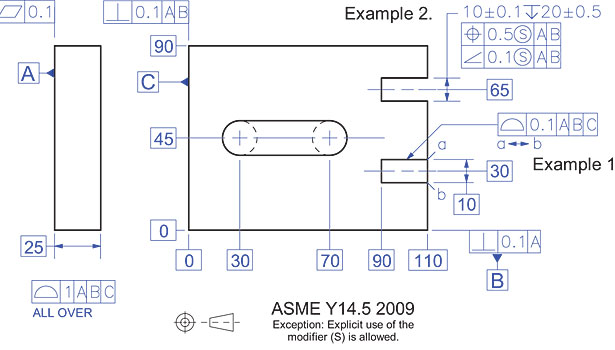

“Why is profile allowed to be designated as one-sided? Can other GD&T symbols also be one-sided?” First, let’s address a couple of points: there are two profile symbols: profile of a line and profile of a surface. Yes, each of them can have the tolerance amount that is unilateral (one-sided) or bilateral (both sides of the intended profile). Also realize that the profile symbols can be “unequal bilateral” where there is tolerance on both sides of the perfect shape, but more tolerance exists on one side. Some examples:

- Profile, desired surface finish and tolerance specifications. Even with these noted walls thickness due to the complexity and the press' that are available some profiles may need more material thickness. 6063 / 6463.045 1.143mm.050 1.27mm.062 1.574mm And the trend continues. Uniform wall thickness.

- OpenVPX Profile Tables: This standard documents variations of Slot, Backplane, and Modules Profiles. As part of the Slot Profile Description, there are also some Connector Modules defined. This document is primarily tables which are referenced by VITA 65.0. ANSI Ratified: ANSI/VITA 66.0-2016: VPX: Optical Interconnect On VPX - Base Standard.

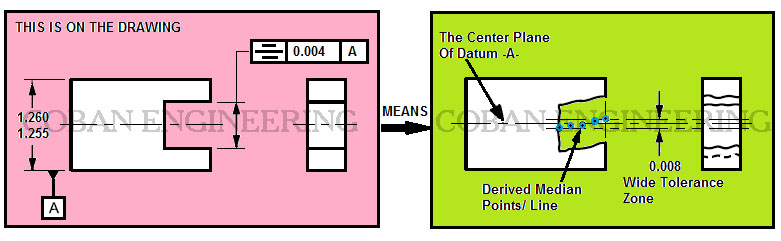

No other GD&T symbol can use these options; there is no such thing as unilateral flatness or unilateral parallelism. Why is that? Well, when we talk about flatness or parallelism, the feature in question has no curvature. So the surface “is where it is.” Profile tolerances, however, have a curve (usually) and also one or more basic dimensions that describe the radius or other values. The prescribed radius is important, and if the curve dips in or out, it is directly impacting the given radius. With this in mind, I should point out the tolerance zones for some other GD&T symbols can float to one side or the other. For instance, a parallelism tolerance of 0.5 allows a surface to tilt 0.5 mm in either direction, but that is not considered a unilateral tolerance, because it is a flat surface. (If it curves in or out, it doesn’t have to follow a particular radius.)

Whether you our your company need a GD&T refresher or a comprehensive training program, please contact us for information about how we can help everyone in your group get on the same page when it comes to the language of GD&T!

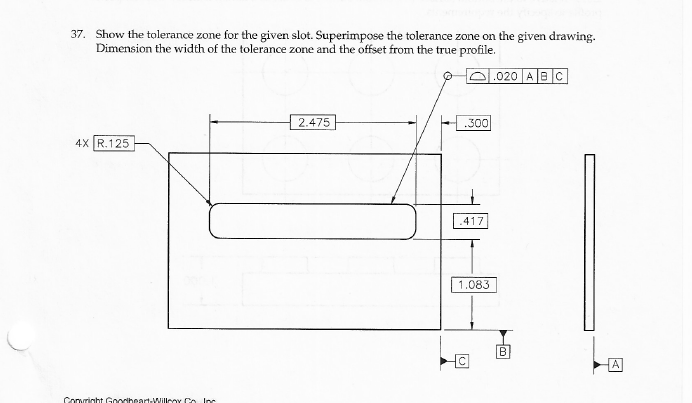

slot call out

slot call out

Slot Profile Tolerance Tool